CUSTOMER REVIEWS

How can you contact us?

Reach us from anywhere:

Email: cal@modprocess.com

Phone: (404) 647-6347

WhatsApp: +1 (404) 647-6347

We’re always available to assist you.

July 2025

BT Design – High-End Furniture for Inspired Interiors

BT Design, Turkey’s leading designer and manufacturer of modern, high-quality furniture, is known for its refined craftsmanship and elegant style. Exporting to over 30 countries, the brand places strong emphasis on product integrity, flawless presentation, and on-time delivery.

Challenge: Complex Product Sizes, Packaging Delays

As BT Design expanded its product lines with more diverse and larger furniture items, standard-sized boxes became a major bottleneck. The company faced:

BT Design, Turkey’s leading designer and manufacturer of modern, high-quality furniture, is known for its refined craftsmanship and elegant style. Exporting to over 30 countries, the brand places strong emphasis on product integrity, flawless presentation, and on-time delivery.

Challenge: Complex Product Sizes, Packaging Delays

As BT Design expanded its product lines with more diverse and larger furniture items, standard-sized boxes became a major bottleneck. The company faced:

- Frequent packaging mismatches

- High inventory and storage costs for boxes in various sizes

- Packaging waste due to oversized boxes

- Risk of product damage during transit

- Delays in preparing shipments for export

ORES – Smart Design, Strong Visual Solutions

Founded in 1992, ORES is a leading Turkish manufacturer in indoor and outdoor visual communication systems. With products ranging from poster frames to exhibition systems and signage panels, ORES supports a wide range of industries.

With its headquarters in Istanbul and production facility in Sakarya, along with logistics hubs in Germany and the UK, ORES blends quality, functionality, and modern designWith its headquarters in Istanbul and production facility in Sakarya, ORES combines quality, functionality, and aesthetics. The company also holds a strong presence in international markets through its logistics centers in Germany and the UK.

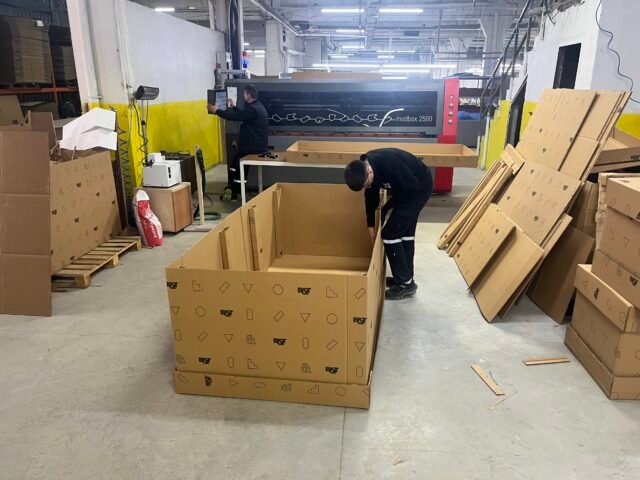

Before implementing Modbox 2500, ORES was managing thousands of cardboard boxes in various sizes and qualities, which led to supply delays and inventory mismatches—especially for order-specific demands. This situation not only increased costs but also caused operational inefficiencies.

Thanks to Modbox 2500, ORES now produces tailor-made corrugated boxes instantly for every product.

Founded in 1992, ORES is a leading Turkish manufacturer in indoor and outdoor visual communication systems. With products ranging from poster frames to exhibition systems and signage panels, ORES supports a wide range of industries.

With its headquarters in Istanbul and production facility in Sakarya, along with logistics hubs in Germany and the UK, ORES blends quality, functionality, and modern designWith its headquarters in Istanbul and production facility in Sakarya, ORES combines quality, functionality, and aesthetics. The company also holds a strong presence in international markets through its logistics centers in Germany and the UK.

Before implementing Modbox 2500, ORES was managing thousands of cardboard boxes in various sizes and qualities, which led to supply delays and inventory mismatches—especially for order-specific demands. This situation not only increased costs but also caused operational inefficiencies.

Thanks to Modbox 2500, ORES now produces tailor-made corrugated boxes instantly for every product.

- The need for box inventory has been completely eliminated,

- Procurement time and packaging costs have been minimized,

- Products waiting in storage before shipment are now safely preserved and protected in custom-sized boxes,

- Unnecessary packaging waste has been reduced—bringing both environmental and cost benefits.

- Significant reduction in packaging waste

- Improved cost-efficiency and sustainability

January 2025

Feltouch

In interior designs, we offer both aesthetic and sustainable solutions by using PET felt made from 50% recycled PET bottles, along with high-quality lighting, ceiling and wall panels, ceiling systems, cladding solutions, and custom-designed products that improve acoustic volume.

In our packaging processes, we adopt an eco-friendly approach by prioritizing the use of corrugated cardboard. However, when shipping internationally, there were instances where standard box sizes were insufficient, requiring us to use larger packaging in terms of volume. This situation both increased our logistics costs and led to unnecessary cardboard consumption.

To address this challenge, we implemented the Modbox 2200 automatic box-making machine. With this advanced solution, we can now produce custom-made boxes perfectly suited to our products, eliminating the need for oversized packaging. The Modbox 2200 allows us to offer flexibility in inventory management, reducing logistics costs, minimizing cardboard waste, and increasing the use of recyclable materials. By integrating the Modbox 2200 into our operations, we are not only enhancing our operational efficiency but also taking a significant step forward in our commitment to eco-friendly practices.

This innovative technology, the Modbox 2200, has enabled us to streamline our packaging process while contributing to environmental sustainability, making it a key part of our environmentally conscious approach.

June 2024

Fuga

In the past, when there were disruptions in the packaging and shipping department of our factory in supplying suitable boxes for each of our products, we were experiencing difficult times in shipments.

We have packaged thousands of products with the machine we have been using since 2020 and we continue with the same ease. Since we produce product-specific boxes instantly with Modbox 2500, we do not bother with supplying boxes according to our measurements. By making special boxes for each of our products and packaging them securely, we have reduced the damages incurred during shipment to almost zero. In this way, we got rid of the problem of stocking parcels and ensured safer product shipment.

S. Alkışel

Mopa

“Previously, we had shelves full of cardboard boxes, not only did they take up space, but we couldn't even count their numbers. Thanks to this machine, we now only have Zform shaped cardboard stock, which we produce as needed. In this way, we both saved space and our stock costs were reduced to almost nothing. Most importantly, we no longer need additional staff for current parcel supply and logistics. “I would definitely recommend it to employees like us.”

O.Güzelbey

Enhance your packaging process and standards with ModProcess’s packaging solutions.

Let’s customize the packaging solution that fits your needs.