Increase productivity

Today’s manufacturing industry is becoming increasingly competitive. An important part of this competition is to increase efficiency and reduce costs in production processes. This is where edge banding machines and line automation systems come into play.

An edge banding machine line automation system has a transformative effect on modern production facilities. By optimising edge banding processes, this system increases the efficiency of your production line while reducing labour costs.

This system is designed to meet the needs of businesses by combining a number of innovative features. Automatic loading and unloading capabilities reduce operator intervention while making your production line more efficient. Intelligent sensors and programmable logic controllers optimise processes and minimise waste.

The edge banding line automation system also has a user-friendly interface that allows operators to do their jobs more efficiently. This reduces staff training time and allows them to learn operations faster.

Choose the edge banding line automation system to increase efficiency and reduce costs on your production line. Discover this innovative solution today for faster, smarter and more competitive production.

2 LP UP 3000

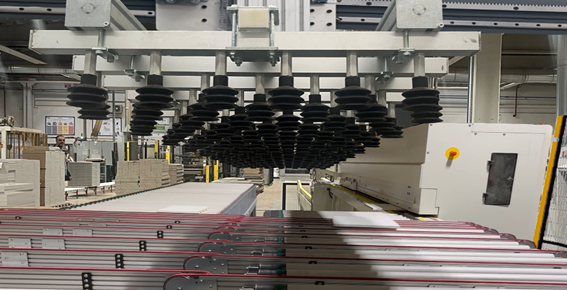

Robotic automation for first and second pass on double sided edge banding lines

This handling robot system is specifically designed to automate the loading and unloading processes on double sided edge banding lines, working together with a continuous panel turner and requiring only a single operator. Its high performance 3 axis robot structure delivers significant time and labor savings for your operation.

BOOMERANG SYSTEM

For edgebanding machines

The Boomerang System is an innovative solution that sets the future standard for edge banding machines. This system, which reduces costs while increasing efficiency, provides a competitive advantage in industrial production and supports the transition to a sustainable production model. In an environment of increasing demand and competition, technological innovations such as the Boomerang System are an essential solution for companies wishing to differentiate themselves in the sector by making their production processes more efficient.

Automation

We always have a solution

With nearly 40 years of industry experience, we manufacture woodworking machines that improve efficiency and support measurable productivity. We focus on practical innovation and customer needs to deliver reliable solutions that fit modern production requirements. Our machines are built for precision and consistent performance.

Find out how the line automation range can help you automate your workflow.

Let us customize the automation solution that is right for you