LP UP SERIES

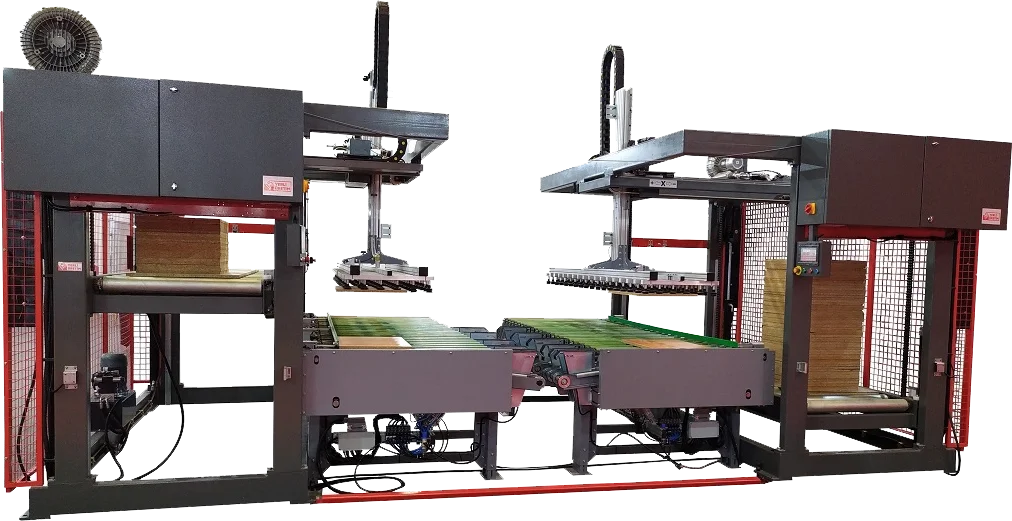

LP UP 3000 Line Boring Machine Automatic Loading and Unloading Robot System

Our handling robot is an automation solution designed to automate loading and unloading operations on through feed boring machines. A single operator can manage multiple machine lines at the same time. This helps keep production flow organized and standardizes the feeding and offloading processes.

The system reduces repetitive manual work for the operator. It lowers labor needs while keeping a consistent pace across shift operations. By minimizing time losses, it reduces waiting time and helps the line run more efficiently.

General features

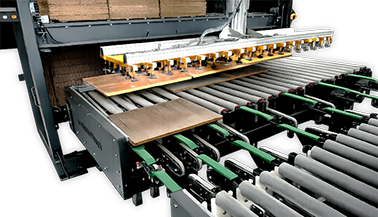

- Operates as an automatic loading and

unloading system for through feed boring

machines. - Works as a loading and unloading system for

edge banding machines together with a

panel turner. - Automatically loads and stacks panels in

single, double, or 3×6 matrix row-stacked

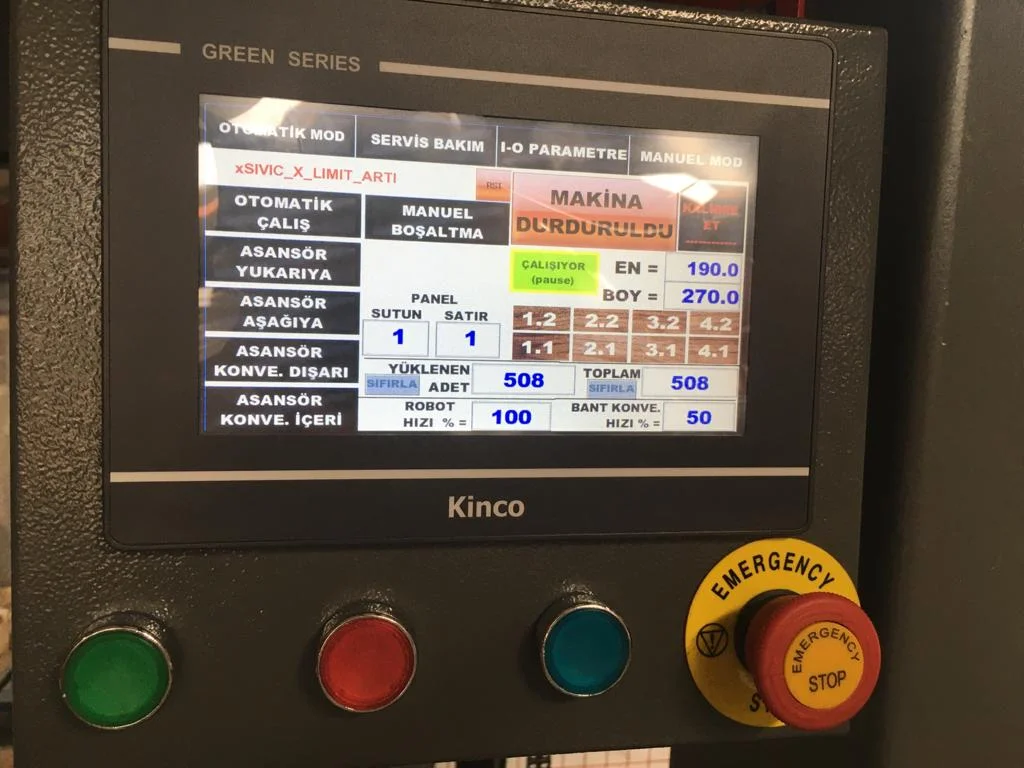

layouts. - Easy to use via PLC touchscreen; all

parameter settings can be adjusted quickly. - Hydraulic stacking platform reduces Z axis

travel, enabling faster stacking cycles.

Production solutions of the future

Automation and robotic technologies are the key to the future in industrial production. Automatic loading and unloading robot systems for through feed boring machines increase the competitiveness of businesses by offering the combination of these technologies. It enables businesses to achieve their goals faster with more efficient, safe and flexible production processes.

Switching to automatic loading and unloading robot systems to optimize the production processes of lthrough feed boring machines and increase efficiency allows businesses to take firmer steps into the future by strengthening their competitive advantages.

Continuous improvement and data analysis

Automated loading and unloading robotic systems support continuous improvement in production processes. They provide comprehensive information about production efficiency thanks to their data collection capabilities integrated into the system. This data helps businesses analyze and optimize their processes. Thus, businesses can continuously increase their competitive advantage by making smarter decisions.

Energy and resource efficiency

Automated loading and unloading robot systems optimize energy and resource usage. Thanks to its smart energy management features, it minimizes energy consumption while also reducing operating costs. Additionally, it ensures efficient use of natural resources by preventing material waste. This both increases environmental sustainability and provides cost savings for the business.

Easy maintenance and service

Our automatic loading and unloading robot system provides easy maintenance and service access. Thanks to their modular structure and remote monitoring features, maintenance processes are optimized and machine downtime is minimized. Additionally, with expert technical support and services, businesses are enabled to maintain uninterrupted production.

Global compatibility and standards

Our automatic loading and unloading robot system is designed and manufactured in accordance with international standards. This ensures access to global markets while also ensuring product quality and reliability. It ensures competitiveness in international trade for businesses and ensures that products are accepted worldwide.

Technical specifications

Panel features to install

- Panel length: between 500-3000 mm

- Panel width: between 300-850 mm (ask different widths)

- Panel thickness: between 10-60 mm

- Panel weight: maximum 40 kg

- Working speed: 6-18 panels per minute

- Vacuum pump power: 7.5 Kw

- Stack height: maximum 1350 mm

- All movment by servo motors

- PLC controlled system

Discover how automatic loading and unloading system will facilitate your production.

Let us customize the loading and unloading solution that will give you speed.