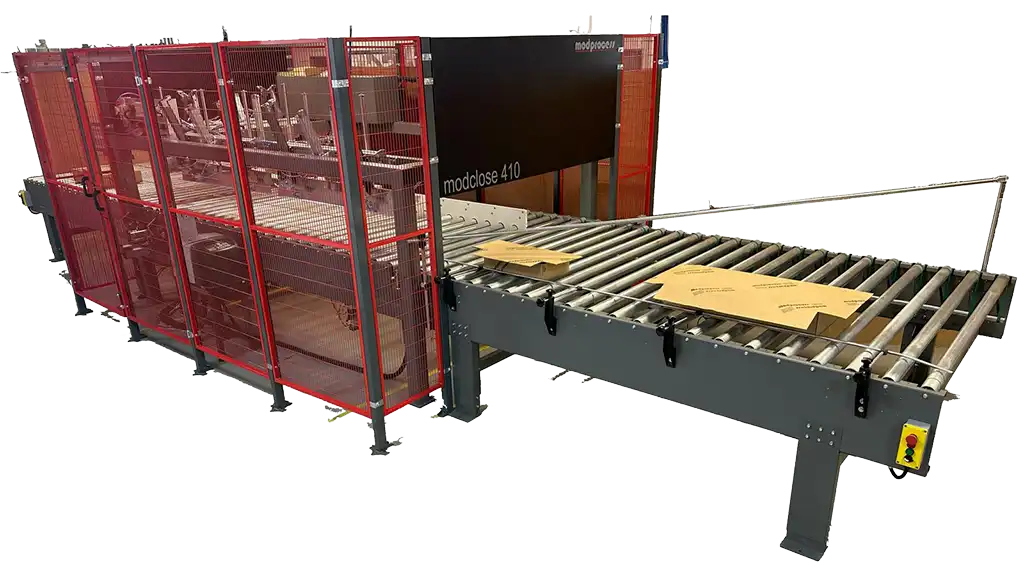

MODCLOSE 410

Automatic Box Closing Machine

It is a system that provides automatic gluing and closing of three edges of the product to be packaged after it is placed in the Fefco 410 box by the operator.

Strong gluing and perfect box closing process for F410 model boxes

Designed to optimise companies’ packaging processes and increase productivity, the MODCLOSE 410 automatic carton closing is a breakthrough solution in terms of reliability and efficiency. This innovative machine automates carton closing processes in industrial production environments, ensuring fast, strong adhesion and consistently reliable packaging.

Faster and less labor intensive than manual processes

The MODCLOSE 410 automatic carton sealer has become an indispensable part of modern production facilities. Thanks to its advanced technology and ease of use, it enables companies to optimise their packaging processes and ensure durable packaging.

MODCLOSE 410

Line equipment:

Manual box preparation and panel loading conveyor

Box closing machine with automatic size adjustment

Label sticking unit (option)

Output discharge conveyor

Features of the box to be packaged:

Box type: Fefco 410

Cardboard thickness: 3- 8 mm

Min. max. package width: 250 – 1200 mm

Min. max. package length: 400 – 2400 mm

Min. max. package height: 35 (25 mm option) – 250 mm

Capacity:

Maximum 8 packs/minute depending on box size

Printing units

Longitudinal side printing unit

consists of 2 units, operates single or double automatically depending on package length

Front and back side side printing units.

The two units work independently of each other, working automatically for two different widths and heights at the same time, without changing settings.

Printing units have the patented angle printing option, which is only available in MODPROCESS. It provides the best adhesion by moving according to the box height and cardboard thickness.

Glue system:

Well-known and widely used brand glue tanks and guns are used.

Glue shots can be applied longitudinally or in interrupted intervals at adjustable lengths and intervals. All settings can be adjusted on the screen in mm.

Especially the front and back side glue gun system is servo mobile, and in service and maintenance mode, it moves out of the machine chassis, allowing easy maintenance and adjustments. This system only exists in ModProcess.

Glue heads are automatically waiting in the parking lot inside the machine in working mode.

Longitudinal side support guard:

The machine moves longitudinally, is servo controlled, moves according to the automatically read box width, and adjusts the box correction and side pressure settings completely independently. These offset values can be easily adjusted on the screen when necessary.

Conveyor system:

It is completely specially designed, steel construction. Each roller is centered from end to end with a 0-16mm diameter inner shaft and is ready for all kinds of heavy working conditions.

The rolls are mounted on independent columns, so they have the infrastructure to be easily adapted to right, left cross conveyor or longitudinal box shipment for all kinds of conveyor and delivery automation.

Control unit:

It has software and PLC system that controls all servo motors and glue dispensing system.

It is very easy to use and is programmed so that offset adjustments and controls of all movements can be easily made from the parameter screen.

All conveyors control 3 independent and 5 servo motors, including the front and back side glue dispensing movement system.

Only ModProcess has all movements with servo motors.

Find out what MODCLOSE 410 can bring to your workflow.

Let us customize the packaging solution that suits you.